Maximize your garage storage space by installing a pulley system, because it’s a practical and efficient way to organize and easily access your stored items.

Key takeaways:

- Maximizes vertical space, improves accessibility, enhances safety, protects equipment, streamlines organization

- Types of pulley systems: bicycle lift, overhead storage platforms, kayak and canoe hoists, heavy-duty pulleys, wall-mounted pulleys

- Essential components: pulleys, rope or cable, mounting brackets, load hook, cleat or locking mechanism, weight capacity labels

- Step-by-step installation: identify location, gather tools, mark drill points, pre-drill holes, attach mounting brackets, assemble pulley, thread rope, attach load hook, test system, adjust as necessary

- Safety considerations: inspect for wear or damage, avoid overloading, operate slowly and steadily, keep area clear, regularly check fixtures and fittings

Benefits of Installing a Pulley System in Your Garage

A pulley system in your garage offers several advantages, enhancing both functionality and space management:

- Maximizes vertical space: By utilizing ceiling height, a pulley system allows you to store bicycles, kayaks, or other bulky equipment off the ground, freeing up valuable floor space for vehicles or work areas.

- Improves accessibility: Items hoisted onto a pulley system can be easily lowered when needed, bypassing the need to climb ladders or move other objects to access overhead storage.

- Enhances safety: Properly secured items on a pulley system reduce the risk of accidents or injuries that can occur from heavy lifting or falling objects.

- Protects equipment: Keeping items off the ground not only saves space but also guards against water damage, pests, and clutter-induced damage.

- Streamlines organization: By providing a designated spot for larger items, a pulley system can help maintain an organized and efficient garage environment.

Types of Pulley Systems for Garage Usage

Bicycle lift pulleys provide a simple way to hoist bikes to the ceiling, maximizing floor space. These systems typically consist of a hook, rope, and a locking mechanism to prevent accidental releases.

Overhead storage platforms operate on a larger scale, lifting bulky items such as storage bins or outdoor equipment. Some designs incorporate a crank, while others may use a more advanced motorized system for lifting heavier loads.

Kayak and canoe hoists feature straps to securely cradle watercraft, ensuring safe storage above. They are designed not just for weight support, but also to maintain the shape of the boat.

Heavy-duty pulley systems are designed for items like engine blocks or large machinery. They generally have a robust build and may feature steel cables and a manual or electric winch for handling substantial weight.

Wall-mounted pulleys are an alternative to ceiling mounts and are ideal for places with limited overhead space or structural limitations. Wall systems can be used to store ladders, garden tools, and other vertically long items.

Each system has its unique installation requirements and operational mechanics tailored to specific storage needs and weight capacities. Selecting the right one depends on the items you plan to lift, the garage space available, and the weight-bearing capacity of the garage structure.

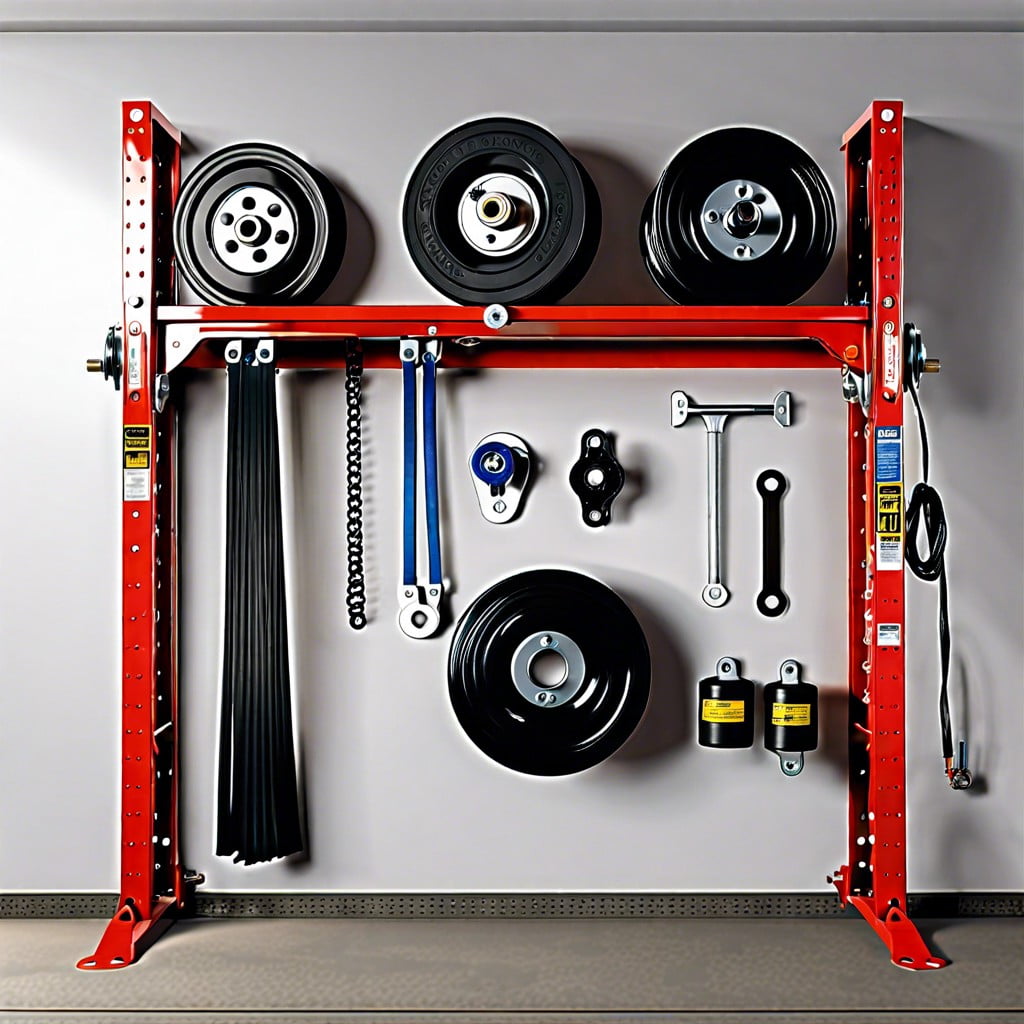

Essential Components of a Garage Pulley System

A comprehensive pulley system hinges on the synergy between its components. The main elements include:

- Pulleys: The wheels with grooved edges where the rope or cable is placed. They reduce effort needed to lift heavy objects.

- Rope or Cable: A strong, durable line that connects to the pulley wheel, vital for hoisting items.

- Mounting Brackets: Secure the system to ceiling joists or walls and must support the weight of stored items.

- Load Hook: This attaches to the item being lifted. It should be robust and securely fastened to avoid slippage.

- Cleat or Locking Mechanism: Used to tie off the rope or cable, preventing the load from descending once lifted.

- Weight Capacity Labels: Ensure proper usage by indicating maximum load limits.

Understanding the role of each component is crucial for designing a system that’s both efficient and secure. Selecting high-quality materials will extend the lifespan of the system and provide peace of mind.

Step-by-Step Guide to Installing a Pulley System

To successfully install a pulley system in your garage, follow these steps:

1. Identify the Installation Location: Choose a sturdy area on the ceiling joists where the system can be securely mounted. Ensure it’s clear of obstructions and within easy reach for operation.

2. Gather Your Tools: You’ll need a drill, drill bits, wrenches, screws, a stud finder, and the pulley system kit.

3. Mark the Drill Points: Use a stud finder to locate the ceiling joists and mark the points for drilling. Ensure they align precisely with the pulley system’s mounting holes.

4. Pre-drill Holes: Pre-drilling helps prevent wood splitting and ensures easy installation of the mounting hardware.

5. Attach Mounting Brackets: Secure the system’s brackets to the ceiling joists using the appropriate screws, as specified in the kit’s manual.

6. Assemble the Pulley: If not pre-assembled, put together the pulley components according to the manufacturer’s instructions.

7. Thread the Rope: Follow the pulley pathway to thread the rope, ensuring smooth operation and that the rope is firmly seated in the pulley grooves.

8. Attach the Load Hook: Secure the hook or platform that will hold the items you’re lifting to the end of the rope. Be sure it’s locked in place and can support the intended weight.

9. Test the System: Before using it to lift any significant weight, test the system with a light object to ensure proper installation and smooth operation.

10. Adjust as Necessary: If the system isn’t working smoothly, re-check all attachments and rope threading, and make any necessary adjustments.

Ensure you follow the manufacturer’s guidelines and weight capacity limits to prevent system failure or accidents.

Safety Considerations When Using a Pulley System

Before operating a pulley system, thoroughly inspect ropes, pulleys, and anchors for signs of wear or damage. Replace any compromised parts immediately to prevent malfunction.

Ensure that the weight capacity of the pulley system is not exceeded. Overloading can lead to equipment failure and potential injury.

Operate the system slowly and steadily to maintain control of the load at all times. Jerky movements can destabilize the system.

Keep the area clear where the load is being lifted or lowered to avoid injury to bystanders or damage to objects below.

Routinely check the system’s fixtures and fittings to ensure they remain tightly secured. Regular maintenance helps prevent unexpected issues.

Use gloves and appropriate safety gear to protect hands from friction burns or cuts when handling ropes.

Educate all users on proper operation techniques and safety measures to ensure a consistent safety standard is upheld in the garage space.

Maintaining and Troubleshooting Your Garage Pulley System

Regular maintenance ensures the longevity and safe operation of your pulley system. Periodically check cables for fraying or signs of wear, and replace them promptly if damaged. Lubricate moving parts, such as pulleys and bearings, to minimize friction and prevent rust. Nuts and bolts should be tightened to avoid slippage or movement that could lead to misalignment.

When troubleshooting, listen for unusual noises that may indicate a problem. If the system sticks or jams, inspect for obstructions or debris that may be causing interference. Check for even weight distribution as imbalanced loads can cause uneven wear or potential failure. In cases where the pulley doesn’t move smoothly, examine the pulley track for bends or damage and rectify any issues to restore proper function.

By staying vigilant and addressing issues promptly, you can enjoy a reliable pulley system that enhances your garage workspace.

Optimizing Garage Space With a Pulley System

Utilizing vertical space is key to maximizing storage capacity, and a pulley system unlocks this potential. By hoisting items such as bicycles, kayaks, or seasonal equipment off the ground, floor space is cleared for vehicles or other necessities.

A pulley system can be particularly advantageous for storing heavy items, as it reduces the need for lifting, thereby minimizing the risk of back strain. Items stored overhead are also less likely to be damaged by water or pests.

Prioritize frequently used items for ground-level storage and relegate less commonly used items to the pulley system. When arranging your space, ensure that items stored aloft do not obstruct garage doors, lights, or power tools. Always label storage containers clearly, and maintain a clear path beneath suspended storage to safeguard from accidents and ensure easy access.

By strategically implementing a pulley system, you can transform your garage from a cluttered catch-all into a neatly organized, multipurpose area.

Cost Comparison of Pulley System Vs. Other Storage Solutions

Comparing the upfront and long-term costs of a pulley system to alternative storage solutions is critical for homeowners. While the initial investment in a quality pulley system may range from $50 to $200, the price can fluctuate based on the system’s complexity and weight capacity. This cost often includes mounting hardware and the pulley mechanism itself.

In contrast, overhead storage racks, which provide a stationary solution, can cost between $100 and $400. These systems require significant space and are less flexible than pulley systems, which can be a limitation for garages with varying storage needs.

Freestanding shelving units are another option, with prices from $40 to over $200, depending on material and size. Although less expensive initially, they consume valuable floor space and may not utilize the garage’s vertical space as efficiently.

For those considering custom built-ins, these can significantly exceed the cost of a pulley system, with custom solutions starting at several hundred dollars and potentially reaching into the thousands.

When considering cost-effectiveness, a pulley system strikes a balance between affordability and space optimization. By leveraging unused overhead space, it avoids the floor space consumption of shelving units and offers more flexibility than stationary racks. Additionally, the potential to avoid long-term costs associated with additional storage solutions or expansions can make pulley systems a smart financial decision for garage organization.

Reviews of Popular Garage Pulley System Brands

When selecting a garage pulley system, it’s valuable to consider products from reputable brands to ensure quality and durability. The RAD Sportz Kayak Hoist Quality Garage Storage Canoe Lift is a standout for its robust construction and ability to hoist up to 125 pounds. It’s an ideal choice for lifting and storing kayaks, canoes, or bicycles.

Another top contender is the Racor – PHL-R, Garage Ceiling Storage Rack Lift, which offers a heavyweight capacity of 250 pounds. This system is lauded for its ease of lifting and safety lock to prevent accidental release. It’s particularly suitable for storing heavy items like storage bins or bulkier sports equipment.

For lighter applications, the Cartman Bike Hoist is both cost-effective and reliable. With a capacity to lift bikes weighing up to 50 pounds, it’s an optimal solution for cyclists looking to save floor space.

Lastly, the Partsam 440 lbs Electric Hoist Crane offers a motorized solution for those requiring more lifting power. This electric hoist is perfect for heavy-duty items and offers the convenience of remote-controlled operation.

By evaluating these brands, consumers can find a pulley system that not only suits their storage needs but also guarantees safety, efficiency, and longevity.

FAQ

How does a garage door use a pulley system?

A garage door utilizes a pulley system in which the pulleys hold cables connected to extension springs that stretch as the door lowers and serve as a counterweight when the door is lifted.

How do you lift heavy objects with pulleys?

To lift heavy objects with pulleys, secure one end of the rope to the upper pulley, let it pass around a lower pulley attached to the object, return it around the upper pulley, and then pull down on the rope to elevate the object.

What does a pulley do?

A pulley is a wheel and rope mechanism used for lifting heavy objects, changing the direction of an applied force, and potentially reducing the force required to lift a weight, often employed in construction.

How do you hang a pulley from a rafter?

To hang a pulley from a rafter, first drill a hole using a bit smaller than the hook shaft, then manually initiate screwing the hook into the hole, and finally insert a screwdriver into the hook's mouth and continue turning for complete installation.

How can one install a pulley system in their garage?

One can install a pulley system in their garage by securing a pulley assembly to the ceiling, attaching a rope or cable, and then anchoring the load (like a bike or storage bin) to the other end of the rope.

What are the critical safety measures to consider when operating a garage pulley system?

Critical safety measures when operating a garage pulley system include ensuring all components are correctly installed, regularly inspecting for wear and damage, not exceeding the system's weight limit, and keeping the area clear of children and pets.

How frequently does a garage pulley system require maintenance and what does this process entail?

A garage pulley system typically requires maintenance once a year, a process that involves inspecting for wear and tear, lubricating the moving parts, and tightening any loose components.